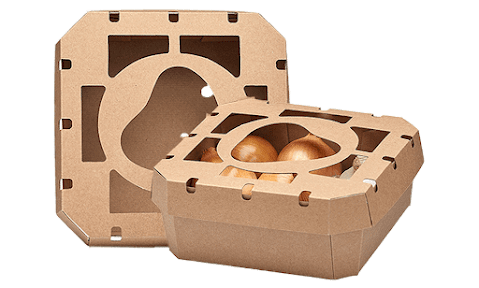

Did you know that some packaging materials aren’t just one or the other? merging fabric, foam, cardboard, and even mesh might seem like a whole recipe for disaster, but it works. And, it can be environmentally sound as well.

Some companies have started with this, such as adding together cardboard as a base, a felt inside to create a soft look, for instance. Mesh and foam are another. Using mesh to help cushion items within the foam means that you can use it in a manner that will keep things safe and secure.

The Uses

A lot of shipping companies will use this.

Electronics are one of them. Lots of times, electronics need that extra little bit of TLC that can help to make the packaging safer for all. So, using hybrid materials means that you have a set amount of space, or a set type of materials, that will help to ensure that the packaging is kept safe and sound.

It also is used in luxury goods. The cardboard box with felt or velvet for instance, enhances the presentation while also keeping such items safe.

Finally, you have temperature-sensitive items.

These are items that, if they get too hot or too cold, can be affected. Using mesh to protect, or wrapping it in foam and putting it in cardboard will help to keep the item from getting to a state where it’s unusable to customers, improving the overall experience.

Why Use This?

A lot of companies are jumping on this because it does enhance the protection. You’re not just using one type of packaging material for this.

The other reason is that it provides a unique form of cushioning. It might be better to combine materials, using felt in place of hard plastics, and it will make things safer.

Finally, it’s aesthetically appealing. Being able to craft an aesthetically appealing experience for your packaging is good. Doing so will enhance the experience for all that’s involved, so definitely work to make your packaging mesh together, to create the ultimate experience.

New Innovations

Some companies have also found that, while hybrids are great, there's also bonding materials that can be used, without the toxic adhesives. It can make your production and compatibility of the packaging types even more profound, and more exciting too. you don’t have to worry about the adhesives being toxic or environmentally unsound. It can, instead, be something that will be eco friendly, and safe not only for humans, but for the overall consumption of such materials as well.

New Trends for Customization

Lots of this customization comes with mixing and matching layers, in order to tailor the product types. You can use different layers, such as maybe a cardboard base, followed by fabric and felt, and then maybe some foam, to help keep the items protected. It’s cool, because depending on the audience and types of experiences you wish to give to others, you’ll definitely succeed with this.

Sometimes, you need to think outside the box, outside of the overall hybrid experiences. Using hybrid materials is not just something that should be used to improve the lives of not only your customers, but the company, but you can create a premium packaging experience that will change the course of things, helping you with improvements of your packaging, and thereby making it more sound.

Try it today, and see if hybrid is the way for your packaging to go, and take into account the factors that need to be in place to make your packaging shine on all fronts when possible.